How the DTF Transfer Process Works From Design to Finished Product

Discover the steps behind Direct-to-Film (DTF) transfers, a popular method for creating vibrant, durable designs on textiles. Learn how digital designs are printed, adhesive is applied, and heat transfer ensures lasting prints on fabrics.

Create DTF Transfers

Create Custom Apparel

Shop our Specialty Transfer Options

DTF Transfers By Size

Whether you are a professional printer or a hobbyist, understanding DTF transfers by size is crucial for producing high-quality, tailored prints. By choosing the right transfer size, you can elevate your projects, ensuring they align perfectly with your creative vision and the specifications of your garments.

-

Understanding DTF Transfer Sizes -

Choosing the Right Size for Your Project -

Custom Sizes -

Tips for Effective Use of DTF Transfers by Size -

Advantages of Choosing the Right Size

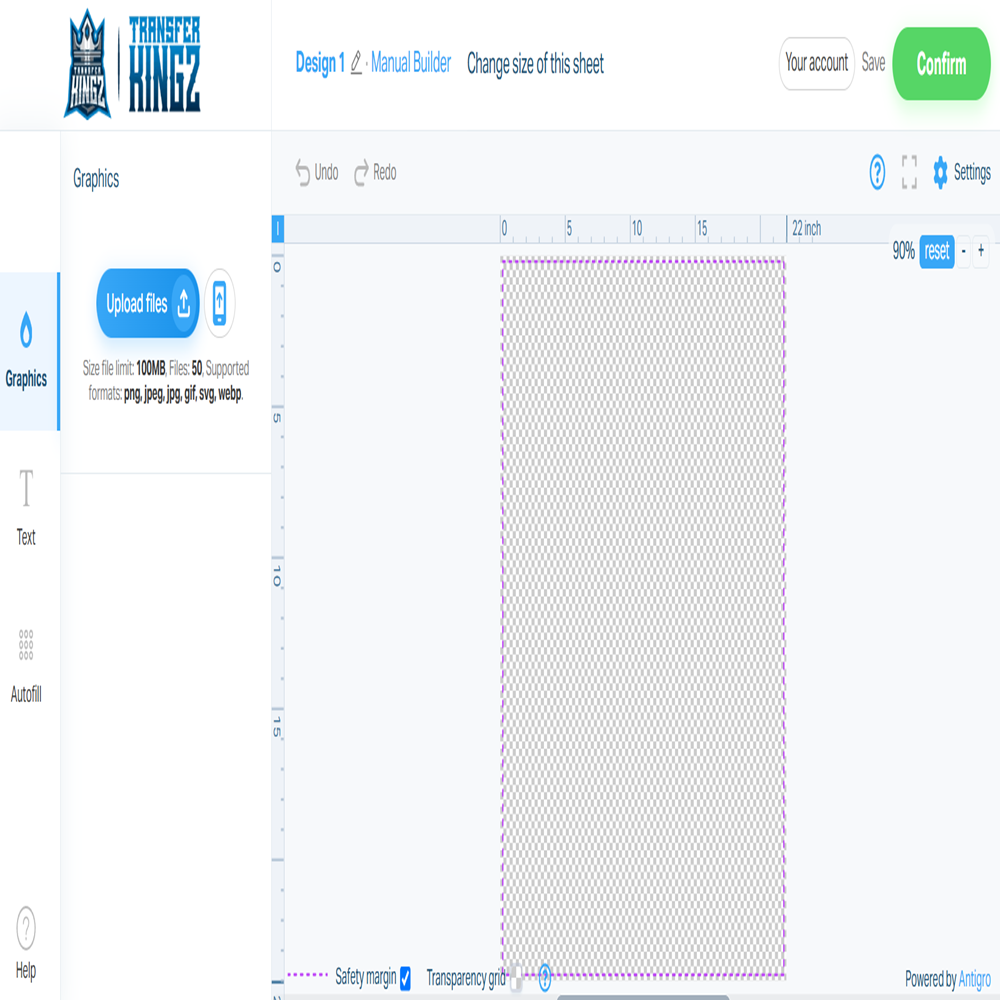

DTF Gang Sheet Online Builder

DTF Gang Sheet Online Builder is a powerful tool for enhancing the efficiency and flexibility of DTF printing. It simplifies the layout process, supports high-quality output, and saves both time and resources, making it an indispensable asset for any custom print operation.

-

Works on Any Fabric or Color -

Transfer Kingz Easy Peel Technology -

100% Satisfaction Guaranteed -

Vibrant Colors & Ultra-fine Details -

Long Lasting Durability -

No Minimums or Setup Fees

How the DTF Transfer Process Works

Design Creation

Prepare a digital design file (often in formats like PNG or AI) with clear resolution for high-quality printing.

Film Printing

Print the design onto a special PET film with colored inks for vivid, accurate detailing.

Adhesive Application

An adhesive layer is applied over the print to ensure strong adhesion to fabrics during transfer.

Curing

The film is passed through a curing oven, activating the adhesive.

Transfer

The printed film is placed on the garment and heat-pressed, transferring the design.

Peeling

After cooling, the film is peeled away, leaving the design on the fabric.

Transfer Kingz DTF Transfer Features

- Print Any Design on Any Garment

Transfer kingz DTF (Direct-to-Film) transfers are incredibly versatile, enabling vibrant and durable prints on any garment or material. Whether it’s cotton, polyester, blends, or even leather, our proprietary adhesive powder and high-quality inks ensure effective bonding with various fabric types.

- Unmatched colors and fine detail

Our transfers deliver unmatched colors and fine detail, ensuring every design is vibrant and precise. Our technology excels in capturing fine lines, gradients, and intricate patterns with exceptional clarity, making even the most complex artwork come to life on any material.

- Easy Application

Our transfers are quick and easy to apply, requiring no weeding or pretreatment. Simply position and press the transfer to achieve professional-quality results far faster than traditional methods.

- Soft to the Touch

DTF transfers provide an amazingly soft hand-feel, resulting in a smooth and comfortable finish. Unlike vinyl transfers and DTG printing, which can leave a stiff or gritty texture, DTF transfers ensure a superior and comfortable finished product.

- Tested to 100+ Washes

Our transfers are designed to maintain their quality and vibrancy through extensive washing, lasting up to and beyond 100 washes. This durability is a testament to our rigorous testing, ensuring our transfers stand up to everyday wear and tear.